Corn Popper:

Rhetorical Analysis & Re-engineering

Overview:

For this project, I reverse-engineered a highly popular child’s toy, the Corn Popper. The purpose of the Corn Popper is to encourage a child to practice walking in a fun and exciting way. Shown below is a picture of the said Corn Popper. As you can see, it is simple in design, yet effective. The bold, brightly colored pieces that make up the toy are specially tuned to appeal to those in the ideal age group, this being young children/toddlers.

Process:

Breakdown & BOm

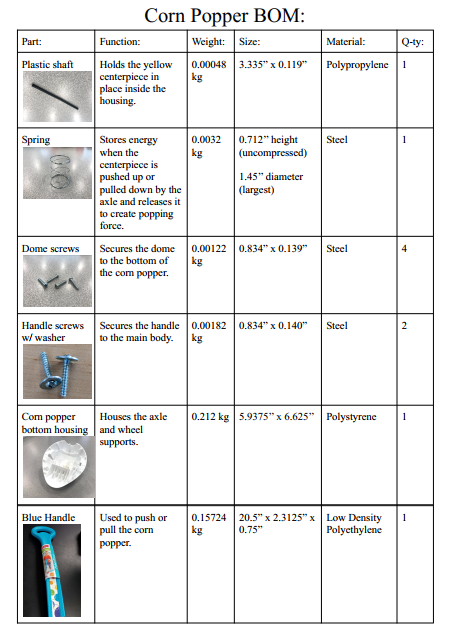

This process invoked the engineer within me, and I found myself asking the question of how the Corn Popper worked. I wanted to know the “Why” and “How”. I excitedly disassembled the toy and wrote down my findings, using what I learned to gain a deeper understanding. The Bill of Materials (BOM) is shown below.

Part 1 of Bill of Materials

Part 2 of Bill of Materials

Life Cycle Analysis

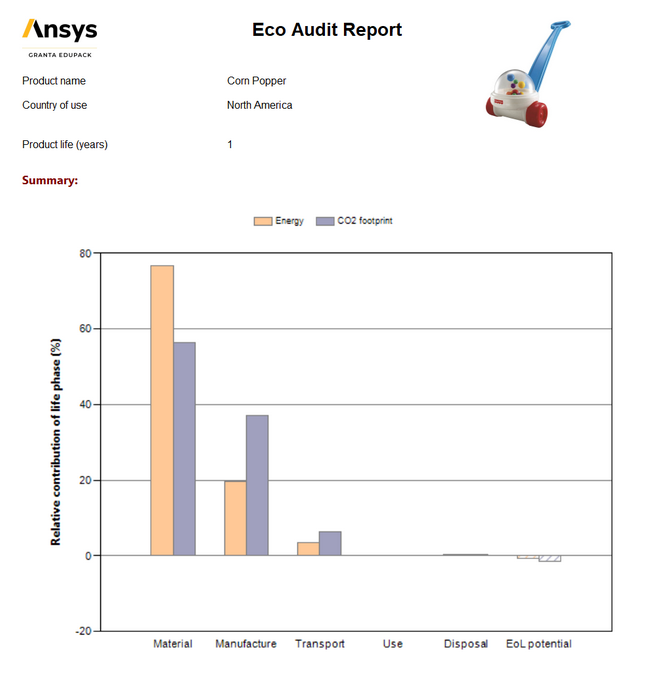

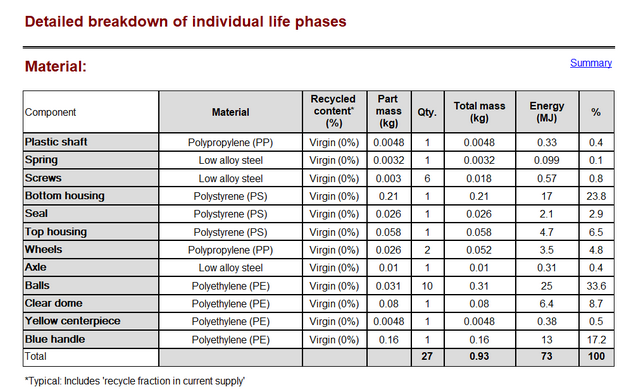

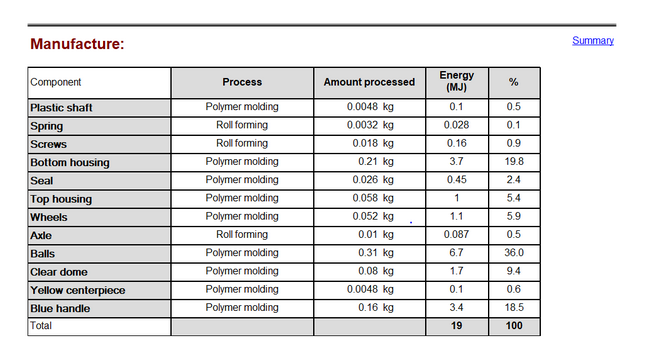

Now equipped with the knowledge of what the Corn Popper is made of, I used the tools available to me, such as the Eco Audit Program (used to analyze an item and break down it’s life phases), as well as researching online to determine what materials made up the toy and where they may have come from.

Energy vs CO2 footprint bar graph

Individual life phase: Disposal & End of life

Individual life phase: Materials

Individual life phase: Manufacture

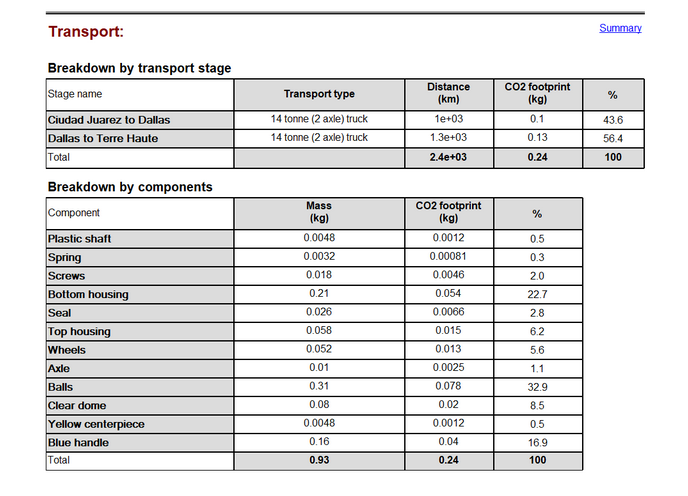

Individual life phase: Transport

As you can see from the graphs and charts, The two largest contributors to the energy waste and the CO2 production of the corn popper are the materials and manufacturing process. In comparison to the impact of the materials and manufacturing of the corn popper, transportation is an insignificant contributing factor to the energy and CO2 factor. For this reason, I decided to focus solely on ways we could improve the materials and the manufacturing.

I believe that this could be reduced by simply re-using reprocessed plastic waste and reusing the materials such as screws, axle, and spring since they are made of hardened steel. Another material that could be used to make the corn popper to reduce its impact is Bio-plastics. It is made up of plant matter such as corn, adds nutritional value to soil, and biodegradability makes it environmentally friendly. Most of the manufacturing process consists of using polymer molding (For the plastic components), and roll forming (for the metal components). A way that could improve upon this is by investing in a compressed air system. This system in a sense generates energy and uses this power to drive an engine or motor. It is more energy-friendly and cost-efficient in the long run of manufacturing.

Explanation & How it works

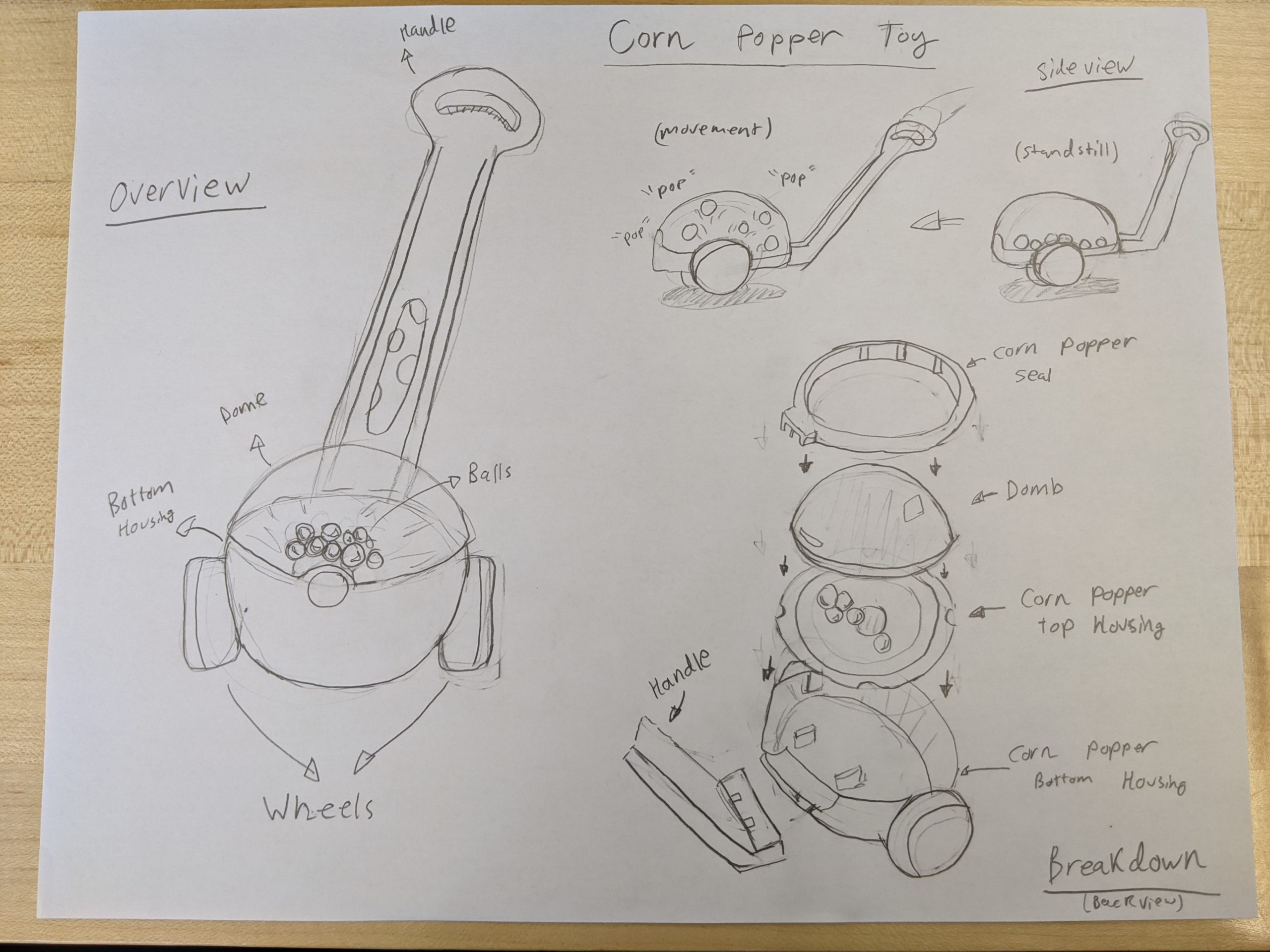

Shown below is a detailed diagram of the corn popper. As you can see, The outside of the corn popper consists of a bottom housing, a top housing, a handle, a dome, a seal, and six screws. The top housing contains the yellow centerpiece which connects to the dome. The dome protects the balls from going all over the place, keeping the balls inside. The corn popper seal holds the corn popper housing and dome together. The purpose of the seal is also to prevent the child from reaching the screws and thus prevent the child from swallowing the balls.

Overview of Corn Popper

Bottom Housing:

Contains the wheels, axle, centerpiece, plastic shaft, and spring.

Top Housing:

Contains the balls, and clips onto the dome.

Proposed additional Features

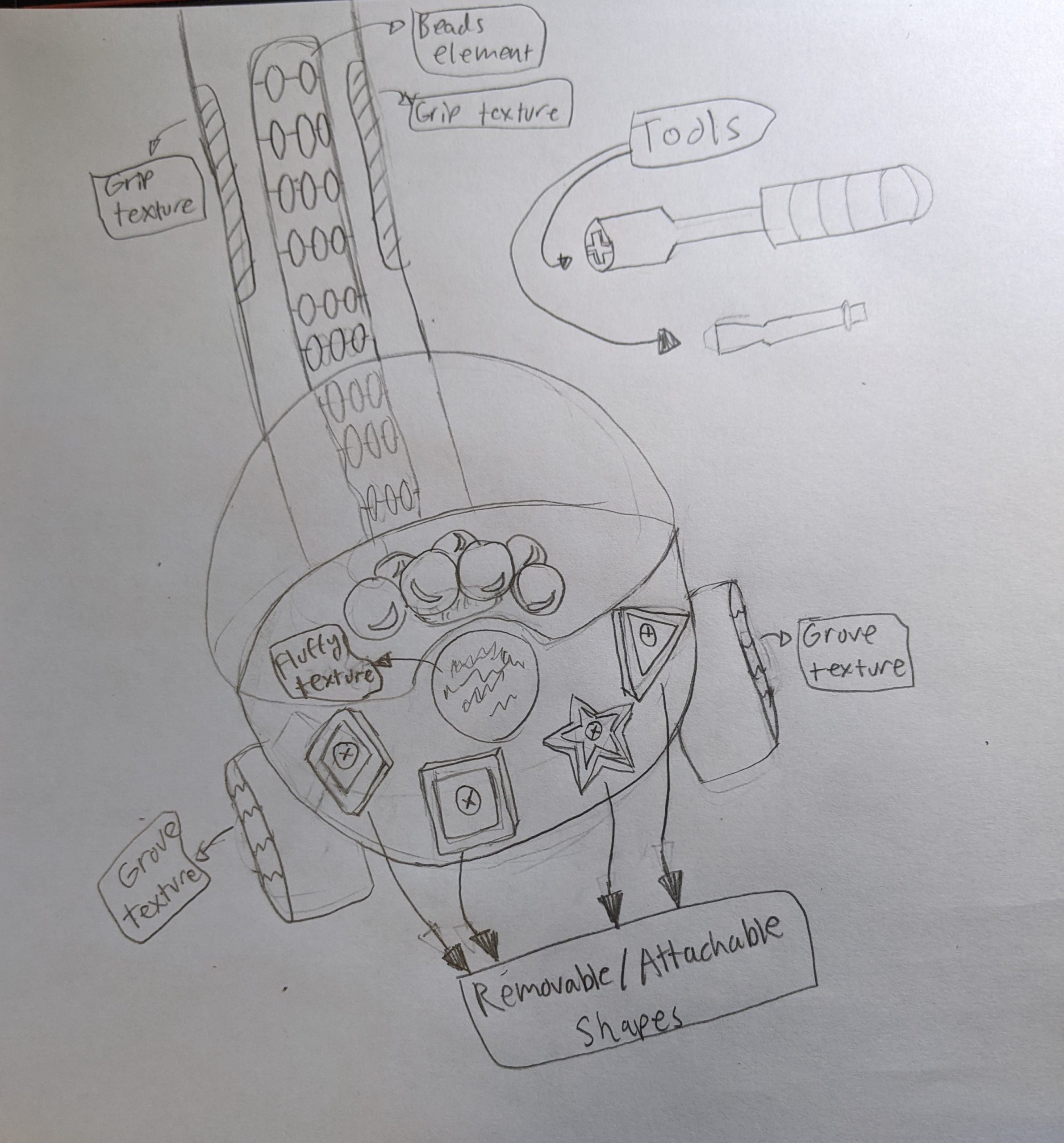

My ideas for the Corn Popper include adding 2 new unique features to the system itself. The first is the ability to assemble/disassemble the corn popper. The child would be able to use the plastic tools that would be included with the corn popper to remove/put on the brightly colored various detachable shapes that would line the sides of the corn popper. Another feature would be having different elements on the corn popper itself to introduce the child to different textures such as groves and bumps. This will allow the child to be familiar and comfortable with these textures as their surroundings change and are introduced to new things.

Concept drawing of proposed added features

Marketing

I would market this redesigned corn popper as a “Newly re-innovated classic toy that allows your little one to tinker and customize to their heart’s desire, all while developing essential skills such as practicing fine motor skills, problem-solving, and creativity. Various special touchpads are now located on high-touch areas of the corn popper to introduce your child to different textures to help them learn and grow familiar with them. This toy is specially designed for children who seek sensory input and stimulation.” The language used is meant to appeal to and target parents of those who may have children on the spectrum but also to parents and grandparents in general. As for how I would reach this audience, I would advertise on the Fisher Price website itself assuming I was redesigning the toy for them, or ask to have a parent’s magazine feature the corn popper as a toy to help stimulate and entertain their child all while improving their hand-eye coordination.

Skills gained & takeaway:

- Learned how to perform life-cycle analysis & diagnostics

- Utilized tools such as Eco Audit and 3C’s Principles

- Created Marketing & Rhetorical Analysis Plan

Tackling such a unique project allowed me to enhance my knowledge of engineering principles, and practice/build upon my design skills, allowing me to use what I learned in class, as well as manage my time effectively to ensure I met the deadlines. I will be able to utilize the strategies and knowledge that I have gained and incorporate it into my next big project, designing and creating toys for children in need.

This opportunity to work with clients will allow me to “Create values” for a subject I hold near and dear to my heart. I am looking forward to being able to work with them and create toys situated to their needs